In April of 2018, Commissioner of the Department of Economic Development Catherine Smith sent a letter to the president of the Connecticut Center for Advanced Technology advising the nonprofit organization to cease and desist using state-owned equipment to perform commercial work for Connecticut manufacturers.

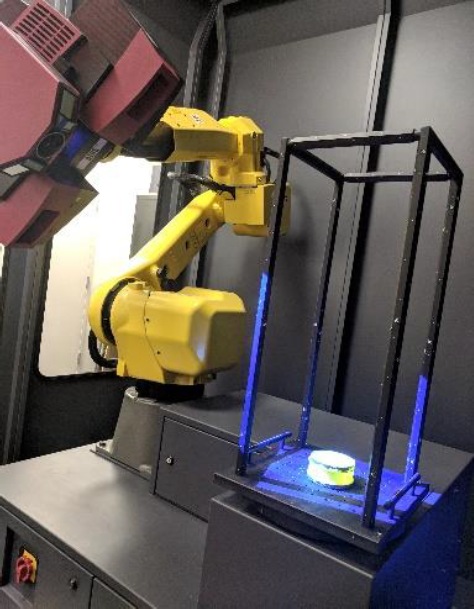

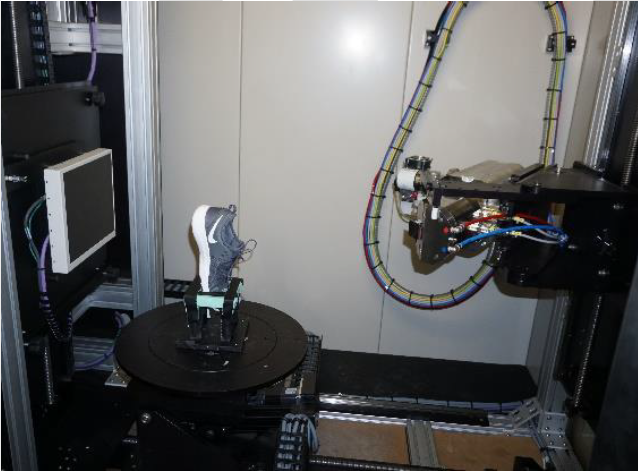

The advanced manufacturing equipment, which included a blue light scanner and an X-Ray scanner had been purchased for nearly $1 million with a $5 million federal grant received by the State of Connecticut and administered through the DECD.

The grant was part of the Regional Aerospace and Defense Exchange program, which sought to create a more regional approach to aerospace and defense manufacturing in New England, streamline supply chains and ensure that companies were utilizing the newest precision technology equipment by providing free demonstrations and trainings with a particular focus on the F-135 jet engine being developed by Pratt & Whitney.

Connecticut awarded a contract for housing and demonstrating the equipment to CCAT, a state and federally funded nonprofit housed at Raytheon’s campus in East Hartford that administers technology grants, education and other forms of aid for Connecticut manufacturers and has been championed by Rep. John Larson, D-CT.

However, DECD became concerned over how the equipment was being used by CCAT following release of a report entitled AMC Success Stories, which outlined how the equipment in question was used to help engineer and design car parts, medical devices and remote-control car parts, rather than being used for aerospace and defense.

“The document highlights non-defense companies and/or projects that don’t appear to be eligible under the terms of our contract,” Smith wrote. “If CCAT has derived any revenue from the use of the equipment in non-eligible ways the proceeds must be returned to DECD. Until this issue is resolved, CCAT will cease and desist using the equipment. In addition, DECD will withhold payments on any contracts nor enter into a new contract with CCAT.”

At the time, CCAT was headed by Elliot Ginsberg, former chief of staff to Larson, who had taken the helm of the nonprofit in 2007. Smith requested a meeting with Ginsberg in May of 2018. The details of the meeting are unknown, but Ginsberg resigned from his role of president shortly thereafter and took over as CCAT’s board chairman, a position he held until 2019. He passed away in 2020.

But it was also not the first time this issue had come up between the DECD and CCAT.

According to a December 2017 email between DECD’s Director of Business Development Barbara Fernandez and CCAT’s Chief Financial Officer John Glidden, Fernandez questioned why Pratt & Whitney was under the impression that CCAT owned a 3D Scanner that was, in fact, property of the state.

Just two months later, Ginsberg sent a letter to Fernandez saying that “At no time has CCAT charged any company an equipment use fee for access to the GOM ATOS or the CT SCAN NSI X500 for CCAT’s own commercial gain.”

Companies had been charged for labor services, Ginsberg wrote, but the work was related to a separate contract CCAT had with the DECD called the Connecticut Manufacturing Supply Chain Integration program, another initiative administered by the CCAT for the purpose of assisting small to mid-sized manufacturers.

The RADE grant ended in 2016 and the contract between DECD and CCAT ended in 2018. The scanner equipment remains property of the State of Connecticut and continues to be housed at CCAT.

But questions remain over how the equipment is being used and whether or not the services being provided by CCAT undercut local supply chain manufacturers who provide similar services for Connecticut’s massive aerospace industry, including defense manufacturers.

Documents show that CCAT was charging manufacturers for scanning projects raising the question of whether the nonprofit is supporting manufacturing companies or, at times, competing with them while ensuring some of its own employees or former employees are given a leg-up.

An ‘Informal Agreement’

Following DECD’s cease-and-desist letter, Ginsberg sent a letter to Smith saying that they did, in fact, “discontinue use of the equipment” on the day they received the letter and that CCAT would reimburse two companies for $7,000 in fees – an amount redacted in the letter but later revealed in an internal audit.

However, documents supplied to Yankee Institute show CCAT was charging defense companies for blue light and X-Ray scanning services while still under contract with the State of Connecticut to demonstrate the technology.

*Note: while Yankee normally publishes source material, we are not doing so in this case because it relates to defense manufacturing*

Between 2017 and early 2018 – the same time period during which DECD was questioning CCAT’s use of state-owned equipment – show CCAT charged Pratt & Whitney more than $28,210 for blue light and X-Ray scanning services.

While CCAT was on hiatus from using the equipment due to the cease-and-desist letter, they still had orders to fulfill. In order to do so, CCAT used the manufacturer of the X-Ray scanner, North Star Imaging in Massachusetts, to complete the orders. NSI completed $17,483 in scanning services for Pratt & Whitney, including a CCAT discount of $1,417.

Following the end of the contract period in April of 2018, CCAT continued to use the equipment. CCAT charged Pratt & Whitney $56,308 and GKN Aerospace $40,000 for blue light and X-Ray scanning of various products, even as the state continued to retain ownership.

Ron Angelo, a former DECD deputy commissioner who took over as president of CCAT following Ginsberg’s resignation, says the RADE funded equipment is being maintained by CCAT “at its own expense,” according to an email.

“These systems are mostly used for training and demonstration purposes for the Connecticut manufacturing supply chain,” Angelo wrote.

DECD also says that manufacturers are charged only for CCAT’s engineering staff time on projects and are not charged for “machine time,” which essentially creates a discounted rate and an incentive for major manufacturers to use CCAT for scanning as opposed to other supply chain companies which might have similar scanning capabilities.

Part of the problem was the DECD never established a plan for what to do with the scanners after the end of the grant period and the contract with CCAT.

According to a 2020 audit of the DECD by the Auditors of Public Accounts, “DECD did not establish a sustainability plan for the use of the RADE-funded equipment prior to the expiration of the grantee’s assistance agreement. The grantee maintained the equipment at its facilities after the end of the grant award.”

In their response, the DECD agreed with the finding but said they had to wait for the federal government’s guidance before they could draft up a sustainability plan, guidance that hadn’t been received when the contract with CCAT ended in April of 2018. As of the 2020 audit, the DECD said that it would produce a sustainability plan.

Meanwhile, CCAT continued to use the equipment, billing Pratt & Whitney $8,950 in August of 2019.

CCAT had been chomping at the bit to ensure the scanners would end up permanently in their hands free of charge.

“CCAT proposes any equipment bought under the OEA RADE program become part of CCAT’s AMC by means of a no-cost transfer,” CCAT wrote in a 2017 grant proposal to the DECD. “The equipment will continue to be used to demonstrate advanced technologies to manufacturers with a particular focus on the F-135 supply base for the same purpose for which it was originally intended.”

“CCAT will use funding from the various federal and state programs to fund this effort as well as appropriate cost share from manufacturers,” the 2017 Proposal for Program Funding & Administration said.

That no-cost transfer never happened, but CCAT continues to use the RADE-funded equipment to perform metrology services for manufacturers, including scanning golf balls.

According to the DECD, they have an “informal agreement” with CCAT to continue to maintain and operate the scanners.

Angelo says the RADE program was a success, with CCAT’s engineers “performing thousands of hours of scanning demonstrations using the two pieces of equipment for the Connecticut manufacturing supply chain.”

But there were some bumps along the way, according to The New England Regional Aerospace and Defense Cluster Initiative Evaluation, a report published in 2017 by the Center for Regional Economic Competitiveness.

According to the report, defense suppliers “distrusted receiving product and process innovation assistance at no cost,” a problem that was remedied through CCAT’s collaboration with Draper Laboratory, a technology and development nonprofit in Cambridge, Massachusetts.

The report also noted that while CCAT staff were trained how to operate the scanners, it “was not sufficient to meet all the companies’ needs.”

“ITC staff were self-taught in some aspects of operating the equipment and associated software,” the report said. “The training provided did not feature the most up-to-date version of the GOM ATOS equipment, and this led instructors to troubleshoot unforeseen issues while delivering training to ITC staff, further complicating comprehension.”

Interestingly, the manufacturer of the blue light scanner – a German company called GOM GmbH – maintains an office in South Windsor just a few miles north of CCAT, which also offers free demonstrations of its products.

Support or Competition?

An essential part of CCAT’s contract with the State of Connecticut was establishing the Innovation Technology Center on CCAT’s campus in East Hartford. That meant evicting Bolton Works, LLC a long-time tenant that specialized in 3-D scanning, to make room for the new scanners.

Owner of Bolton Works, Mark Bliek, balked at the eviction, complaining to DECD that CCAT was not only forcing him to move his business but also poaching his customers, which included Pratt & Whitney.

In their response to DECD’s inquiry regarding CCAT’s support of Bolton Works over the years, the nonprofit wrote that CMSCI – the same program under which CCAT charged smaller manufacturers for scanning services and for which it received the cease-and-desist letter – was “part of CCAT’s mission to demonstrate manufacturing technologies to SMF’s and not intended to provide ongoing production capacity to compete with for-profit providers of metrology services.”

They also pointed out that Bolton Works did not have a blue light scanner, which CCAT received courtesy of taxpayers.

In 2019 testimony submitted by the Connecticut Business and Industry Association in support of appointing a Connecticut Secretary of Manufacturing, Bliek laid out his multi-page criticism of CCAT. “For years CCAT was able to siphon funds from the federal and state government under the cloak of a non-profit. Funds which could have been put to good use, have been wasted,” Bliek wrote. “An organization like CCAT is masking the true difficulties businesses are facing in Connecticut.”

Although CCAT had received $48.6 million through federal and state grants between 2015 and 2018, according to their 990 tax forms, the non-profit did establish a for-profit subsidiary called Novus Insight, a creation of CCAT’s Information Technology department in 2018.

According to an audit, CCAT sold the company to its former IT director Dan Salazar in 2020 for roughly $1 million, including a sweep of Novus’ checking account of $433,000, according to an audit.

While creation of a new business is always welcome, the company essentially emerged fully formed and ready to go out of CCAT, created with federal and state tax dollars and with access to a potential customer base. According to the company’s website, it now has 50 employees with offices in both Connecticut and Florida, working with schools, municipalities, nonprofits and manufacturers.

Also mentioned in the state auditors’ report was the state’s purchase of a Zimmerman milling machine at a cost of $2.9 million, which would also be housed at CCAT for purposes of demonstration.

The milling machine, however, was only used once in two years, causing auditors to question the purpose of the expenditure. The Zimmerman machine remains housed at CCAT where it is leased to ACMT, Inc, a manufacturing company co-owned by Paul Paulo, a CCAT board member who also leases space at CCAT.

CCAT board members have also been the recipients of some of those grants. Since 2016, board members have received $96,556 in pass through grants, including ACMT.

Another ex-board member – John Carson of the University of Hartford – also leases space from CCAT, while another board member is contracted for legal services by CCAT, according to 990 forms.

Money Continues to Flow

Between 2012 and 2019, CCAT has received nearly $81 million in gifts, grants and contributions, according to a review of their tax filings, which supports a number of grant programs for Connecticut manufacturers, workforce development through STEM education for schools, energy planning, and utilizing the advanced equipment at their centers to provide services for manufacturers.

Furthermore, the organization helps administer state grants using bonded funds through the Connecticut Manufacturing Innovation Fund. Don Balducci, former of head of CCAT’s Advanced Manufacturing Center, is a board member of the MIF.

Revenue into the nonprofit has ebbed and flowed over the years. In 2015, CCAT took in $13.2 million in revenue. By 2019, revenue had dropped to $6.8 million, before bumping back up to $11.1 million in 2020, according to the state’s Open Checkbook website.

The 2019 budget saw DECD slip in $200,000 in support to CCAT for manufacturing supply chain support.

The organization took a PPP loan of $563,763 in 2020 and a second PPP loan of $467,440 in 2021, according to an audit, and another $1 million through the American Rescue Plan, according to the Connecticut budget. And in 2021, Larson announced CCAT would receive $900,000 for the Connecticut Manufacturing & Technology CommUNITY eCommons, a project that “would reinvent the workforce talent pipeline for small businesses post-COVID-19,” according to the press release.

In 2021, CCAT announced a $5 million project with Pratt & Whitney and Goodwin University to open the Advanced Composites Center, also in East Hartford, in an effort to train workers for the aerospace industry.

So, federal and state money continues to flow into and out of CCAT for the laudable purpose of enhancing Connecticut’s aerospace and technology sector.

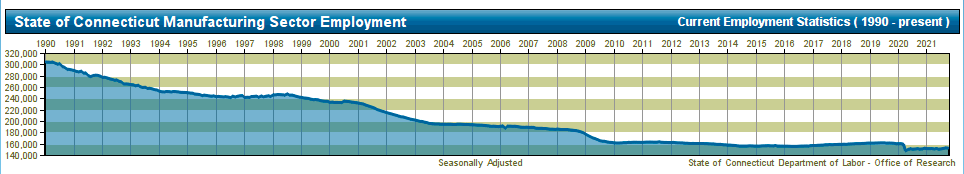

Since the establishment of CCAT in 2004, Connecticut’s manufacturing industry has hobbled along, with employers saying they lack suitable employees. Employment in Connecticut’s manufacturing sector has continued a downward slide since 1990, declining from roughly 300,000 jobs in 1990 to 153,000 in the most recent employment numbers from the Connecticut Department of Labor.

With such a sustained loss, it makes sense that lawmakers would want to bolster this vital industry. What is unclear is what oversight exists as to how funds meant to prop up the manufacturing sector are being used, to what purpose, and whether or not the spending is effective.

With millions of taxpayer dollars on the table and CCAT working hand in hand with the State of Connecticut, it’s fair to ask whether a nonprofit program popular with politicians eager to support one of Connecticut’s biggest industries is actually advancing state and federal economic goals or is rather just banking on that popularity.